Soap making is fairly easy when you know the basic ingredients for cold process soap making. This can be contradictory to what you may have heard, but after making soap for a while you will come to the same conclusion.

The simplicity of making soap is so basic that most persons are confused that it doesn’t take much to make handmade soap.

Whichever method you may prefer, cold process, hot process, melt and pour or even liquid soap making. Each of the types of soaps have the same basic ingredients.

The 3 basic ingredients for cold process soap making are

- Water

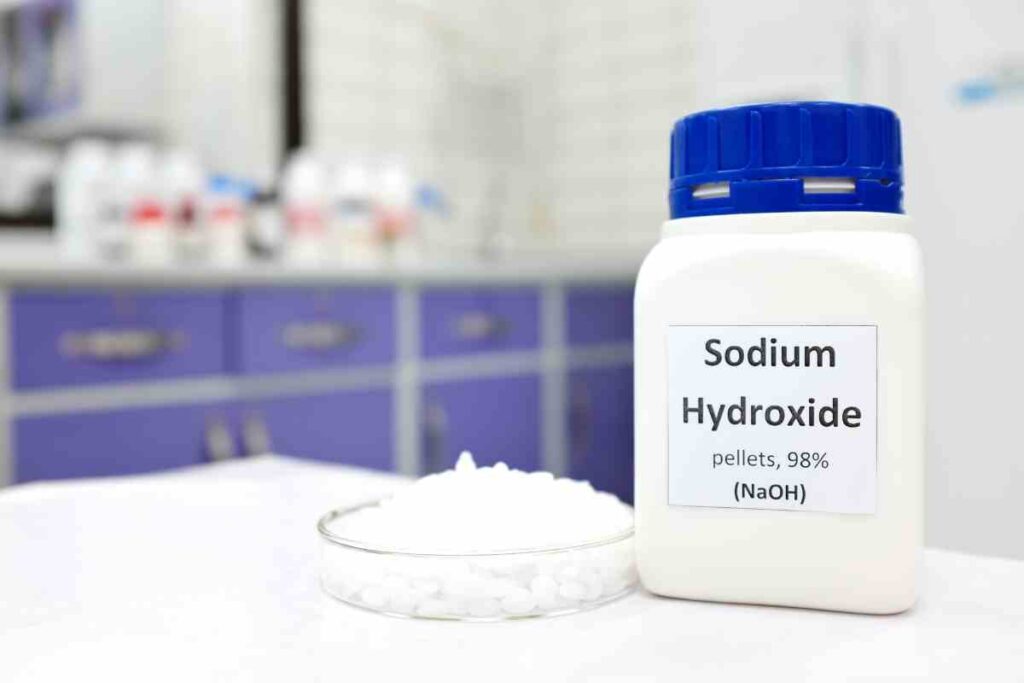

- Sodium hydroxide aka lye

- Fats (animal or plant based)

Basic ingredients for cold process soap making – Water

Water is by far plays an important role in the overall soap making process. However, it is not actually the most important.

This is because water is the foundation of making soap however it can be substituted by other liquids to as a bit of flavor to the overall soap.

Water seems simple enough however it can become far more complicated than you may think.

Not all water is created the same. You can read more about water and soap making in another article about using Distilled water for soap making here on the website.

Types of water

When it comes to soap making there are as many types of water as you can think of that can be used. Distilled water is the gold standard when it comes to soap making while rainwater is considered the closest to nature (this is not true).

The various types of water that can be used are

- Distilled water

- Purified water

- Mineral water

- Rainwater

- Well water

- Spring water

- Sparkling water

Although all these types of waters are all technically water it’s the substances that are dissolved in them that can cause issues in your soap making.

As an example, mineral water and even rain or well water may contain high traces of dissolved solids that may react with lye to cause an unexpected affect.

This is why distilled water is considered the gold standard as it has no dissolved solids to react with lye unexpectedly hence its relatively safer than most other water or liquids that can be used.

Although water is often the main ingredient in cold process soap making other liquids can be used such as milk, wine, beer etc.

Cure time for cold process soap

Soap curing sounds like a complicated process but its actually the time it takes for the lye to completely combine with the fats to make soap and for the water used to evaporate from the bar of soap.

As you set your bars of soap out to cure, if you measure the weight of the soap from week to week you will notice very subtle drop in the weight.

This drop in weight is due to the water used in the soap making process evaporating from the bar of soap.

With a new product produced from water, fats and lye. The water will take some time to evaporate into the air from the soap itself.

The longer you let your soap sit and cure, dry out, the harder it will become and the longer it will last in the shower.

A softer bar with more water will become softer as it absorbs moisture from usage. However, a soap that is dry from the inside out will not be so easily soften and remain hard.

Basic ingredients for cold process soap making – Lye

Lye… caustic soda and its chemical name sodium hydroxide is by far the most important ingredient needed for the soap making process.

This chemical can be substituted when making liquid soap for potassium hydroxide however sodium hydroxide is the chemical to have to make real soap.

How Lye works in soap

By itself, lye is a dangerous substance. However, when combined with water by dissolving the lye it becomes super-heated.

This heat is needed to help bind the lye (alkali) to the fats from the oils or actual fats and make a new substance called soap.

Lye is reactive to certain elements particularly aluminum. This is why using distilled water is so important, depending on where your life. Well water or even rainwater may contain traces of aluminum in it.

This will definitely cause a minor reaction one that if you are not trained to see will produce hydrogen gas.

Hydrogen gas is very flammable however because it is lighter than standard air it disperses rather quickly. Working in an enclosed space with traces of aluminum in water may cause a buildup of hydrogen gas depending on the size of your lye water mixture.

They lye although it can be dangerous, when handled with caution and care is the prime ingredient in the saponification process which makes soap.

Dangers of lye

Touching on some of the dangers of using lye such as its reaction with aluminum is just one issue.

The biggest issue is that sodium hydroxide begins to react with moisture even the moisture in a humid environment.

This reaction causes the moisture or water to heat up producing heat. This heat is what most persons are afraid of but it’s not their top fear.

The heat produced is necessary for the saponification process however this same heat if lye was to get on your skin and react with your skin will itch at first and then begin to sting and then burn.

This is with just one small pearl droplet of lye. With larger doses of lye on the skin reacting with sweat and the humid environment. It can cause sever skin burns.

Hand protection i.e., gloves should be ward at all times when handling lye as well as eye wear and long sleeves if your time will be prolonged.

You can learn more about the usage of Lye in this article here on the website. All you need to know about sodium hydroxide.

Basic ingredients for cold process soap making – Fats

Using the phrase fats, as an ingredient for soap making is oversimplifying the matter. Fats used in soap making pertains to vegetable oils, butters or actual animal fats.

The list of fats can be quite extensive however some that you may recognize are;

- Olive oil

- Coconut oil

- Castor oil

- Sweet almond oil

- Grape seed oil

- Sunflower seed oil

- Avacado Oil

- Black cumin seed oil

- Brazil nut oil

- Camelina seed oil

- Canola oil

- Carrot seed oil

- Corn OIl

- Flax oil

- Hazelnut oil

- Hemp oil

- Jojoba oil

- Mango seed oil

- Palm oil

- Poppy seed oil

- Pumpkin oil

- Chicken fat

- Rabbit fat

- Tallow (beef, deer, goat or sheep)

- Pine tar

- Cocoa butter

- Shea butter

- … and more

Each of the fats have unique properties that can be manifested in the final bar of soap. This is what makes using the cold process soap method such a popular method.

The fats used are chemically converted into a new substance that is called soap. This is the basic essence of how soap is made using the cold process method.

Water, combined with lye creates heat. The heat and the fats allow the lye to combine and make a new substance that we use as soap.